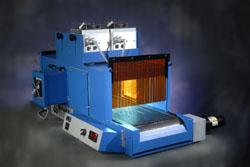

UVCS SideCure Conveyor System

Description

When the job calls for 180-deg. curing, the UVCS SideCure conveyor system handles the job. Designed for UV curing of DYMAX adhesives and coatings from the left, right, and/or top, the SideCure conveyor can be outfitted with up to eight 5000-EC UV curing flood lamps. The conveyor's 12-in. wide belt and 7.5-in. vertical clearance, with 5-in. high side-curing capability, allows for the curing of large parts and makes the SideCure a very versatile UV curing solution.

In addition, the relatively small conveyor size—51 x 30 x 21.5 in.—minimizes the footprint required for UV curing. The use of the conveyor system can often eliminate potential “shadowed areas” around components that are detrimental to a light-curing process.

The high-intensity 5000-EC lamps used with the conveyor provide 225 mW/cm2 of intensity for fast UV curing as well as complete shielding from UV light and consistent exposure times. The SideCure conveyor can be outfitted with up to four 5000-EC lamps on top and up to four 5000-EC lamps on the sides. When 5000-EC lamps are configured in series, the conveyor belt speeds can often be doubled.

The SideCure conveyor system is ideal for bonding, masking, and coating applications in the medical, electronic, industrial, and aerospace industries where 180-deg. UV curing is required.

Specs

| Maximum UVA Intensity / (320-395 nm)1 | 200 mW/cm² |

|---|---|

| Line Speed | 1 to 27 fpm |

| Illuminated Width (from top) | 6 in or 12 in (depending on the number and orientation of the 5000-EC UV lamps) |

| Voltage | Lamp(s) – 90V to 260V | Conveyor – 120V or 220/230V |

| Maximum Parts Height | 7 in. |

| Overall Dimensions | 51 L x 30 W x 21.5 in. H (130 x 76 x 55 cm) |

- Available globally (except Europe)

- Consistent UV curing on the left, right, and/or top—allows for 180-deg. UV curing

- Optical encoder-controlled speed indicator provides for accurate and consistent exposure time

- Can house 1 to 8 UV curing lamps—versatile and scalable

- Configured with high-intensity 5000-EC lamps which provide 225 mW/cm² for fast UV curing

- Adjustable side lamps (3 to 6 in. from belt center)

- 12 in. belt and 7.5 in. vertical clearance allows for curing of large parts

- Small, 4-ft long, bench-top size minimizes the footprint required for UV curing

- Integral cooling and vacuum hold-down

- Complete UV shielding

- Bench-top conveyor (cart optional)