Case Study: Finding the Savings in Part Marking

Description

A major Tier One automotive supplier was required by its customers to mark each of a family of plastic body panels that it produced with a 2-D Data Matrix bar code. In the past, the supplier met this requirement by paying its injection molding supplier additional cost per part to apply coded stickers on each panel. Searching for a better solution, the supplier contacted ICS Laser Technologies Inc., which had been developing this process over the past several years. As a result ICS was able to provide dependable rapid scanning of data matrix codes molded in plastic, thus reducing substantial label costs, especially in high volume conditions. ICS with its various lasers, including its 5-axis laser ablation system, is able to ablate the negative image of a 2-D code into either the mold surface or more interestingly onto the end of ejector pins. This direct part marking (DPM) created relatively low-contrast bar codes that were difficult to read with a handheld ID reader throughout the supply chain. The problem was solved by using the dark field lighting capability of the Cognex DataMan 8600 series ID readers, which makes the barcode stand out in the same way that an automotive headlight illuminates bumps in the road. “The new direct part marking method eliminated the need for stickers, saving over $1 million on a single family of parts,” said Ryan Treece, ID Sales Engineer for Cognex.

Part marking challenges

Today’s automobiles are made of more than 10,000 components. Many of these components need to be permanently marked to monitor supplier quality and to provide traceability. The markings are required to remain intact during the entire life of the vehicle and, in many cases, have to withstand exposure to high and low temperatures, and automotive fluids. The traditional approach to marking these parts is printing large numbers of adhesive stickers with the code and applying them to the part prior to assembly in the vehicle. However, these stickers have a significant cost and, in addition, they take up space for storage, manpower to deliver them to the point of installation, and time to install. In many cases, the stickers are not considered permanent because they have a tendency to tear, become discolored, and fall off.

CNC machining generally cannot be used to machine 2-D Data Matrix codes because producing the floor finish and the intricate texture structure demands a tool so small that it would be difficult or impossible to achieve reliable and accurate machining. On the other hand, 2-D Data Matrix codes can be produced with laser ablation which removes material from a solid surface by irradiating it with a laser beam. “By extensive ablating, molding, and test scanning we have successfully created micro geometry conducive to rapid scanning in milliseconds,” said Brendan Watts, Creative Director for ICS. “As a laser ablation service bureau, we have invested in the latest 5-axis laser ablation technology that is capable of producing very small 2-D Data Matrix barcodes. One challenge we ran into in the early stages of our testing program was the lack of contrast between the molded and the base material so reading the code was difficult. We did find several fixed mount vision based scanners that could read the codes by applying low angle dark field lighting but we had difficulty finding this capability on a handheld ID reader.”

Code reading lighting options

When codes are printed on a label the color of the code and the color of the ink are usually selected to provide a high contrast, such as black ink on a white background. These codes are normally read with bright field lighting that projects at 90 degrees to the marked surface and then reflects back up to the camera. Bright-field lighting is generally defined as lighting from a source oriented at greater than 45 degrees relative to the object of interest. It is called bright field lighting because most of the light is reflected towards the camera, making the image bright.

On the other hand, when codes are permanently marked on a part, a technique known as Direct Part Marking (DPM), there is no opportunity to select the color of either the code or the background. This often makes codes much more difficult to read. In fixed mount reader applications, testing is usually performed with different types of lighting and the proper lighting components are purchased and installed. In this application, the auto supplier needed to provide operators throughout its own and its customer’s plants with the ability to easily read the codes with handheld ID readers.

Dark field lighting solves problem

ICS Laser accomplished this goal with Cognex DataMan 8600 Series handheld bar readers. These ID readers are the first to provide dark field lighting in a handheld barcode reader. Dark field lighting is defined as lighting from a source oriented at less than 45 degrees relative to the object of interest. The DataMan 8600 projects light at an angle of 30 degrees to the marked surface. With dark field lighting most of the light reflects away from the camera so the image is a dark field. In DPM applications, dark field lighting has the advantage that the individual surface details reflect differently from the overall surfaces because some of the light reflected off these surface details reaches the camera. This effect increases the contrast of dot peen or laser marks that are difficult to see in bright-field lighting. In the case of 2-D Data Matrix code molded into dark plastic, dark field lighting highlights the code as a bright, easily detected feature within a dark background. Similarly, automotive headlights shining at low angles to the road surface identify surface imperfections and obstructions in the road.

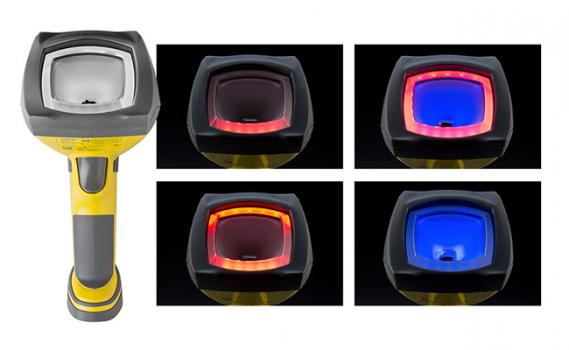

In addition to dark field lighting, DataMan 8600 readers also provide bright-field and dome lighting. Bright-field lighting projects at 90 degrees to the marked surface and then reflects back up to the image to handle high-contrast labels and marks. Dome lighting, also known as cloudy-day or diffused-off-axis illumination, projects light from many different directions to negate reflections and shadows. This technique provides even lighting across curved reflective surfaces to simulate flat objects. Out of the box, the DataMan 8600 comes with four preset lighting defaults enabled. Users can also adjust lighting settings manually by turning on and off lighting quadrants and adjusting the light intensity. This makes it possible to read a wide range of marked surfaces – dot peen, laser etched, ink jet, on glass, smooth or rough metal and shiny surfaces.

New code reading algorithm

DataMan 8600 readers also include the 2DMax+ reading algorithm with PowerGrid technology that overcomes challenges such as poor marking quality or damaged clocking patterns on 2-D codes. This algorithm handles a wide range of degradations to the appearance of 2-D DPM or printed codes, even Data Matrix codes with missing finder patterns or timing/clocking patterns. It also finds and reads Data Matrix codes that are overexposed and underexposed without multiple retries, improving throughput, speed and overall reliability.

In addition, DataMan 8600 readers use liquid lens variable autofocus technology that improves read rates by increasing depth of field. The liquid lens uses two iso-density liquids — oil is an insulator while water is a conductor. Varying the voltage across the liquid-liquid interface leads to a change of curvature, which in turn changes the focal length of the installed optical lens. The liquid lens keeps the code in focus even when the distance from the camera to the code is changing.

“The injection molding supplier ships an injector pin to our facility,” Watts said. “We use a 5-axis laser ablation machine to mill the negative of a tiny 2-D matrix code into the pin and ship it back to the injection molder. From that point on, every part is produced with the code.” The DataMan 8600 handheld scanners provide near 100% read rates and can read the codes nearly instantaneously. The automotive supplier has eliminated the need to purchase labels and the time required to install the labels. The DPM codes are also expected to be much more durable than the paper stickers. The automotive supplier is pleased with this application and considering using this method on additional parts.