CLOG-FREE SPRAY MARKING SYSTEM PREVENTS SKIPPED SHOTS, REDUCES MAINTENANCE AND DOWNTIME

Description

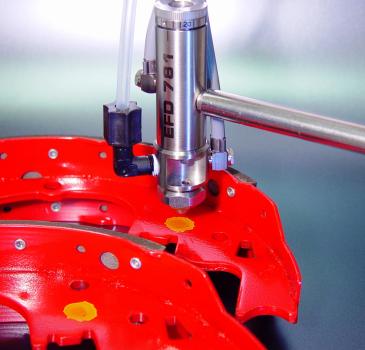

Applications at which the MicroMark excels include color-coding to differentiate between similar components, indicating pass/fail status, and showing whether a specific process has been performed.

The MicroMark uses a precision spray valve and Low Volume Low Pressure (LVLP) air to make uniform spots and stripes without mist or overspray. The system’s high transfer efficiency and quick cutoff improve part appearance and keep work areas clean. A short microburst of air after each shot keeps the nozzle from clogging and reduces maintenance.

The MicroMark system includes a microprocessor-based controller that simplifies system setup and operation. The controller can be easily interfaced with a Programmable Logic Controller (PLC) if desired. Ink or paint is supplied from a fluid tank with a constant-bleed air regulator that prevents fluctuations in fluid pressure.Specs

• Size: 104.6 mm x 26.9 mm diameter (4.12" x 1.06") • Weight: 235.3 grams (8.29 oz) • Actuating air pressure required: 70 to 90 psi (4.8 to 6.2 bar) • Maximum input fluid pressure: 300 psi (20.7 bar) • Fluid inlet thread: 1/8 NPT female • Mounting: (1) 1/4-28 UNF tapped hole or adjustable • mounting block • Cycle rate: Exceeds 400 per minute • Air cylinder body: Hard-coated aluminum • Fluid body: Hard-coated aluminum • Air cap: Type 303 stainless steel • Piston: Type 303 stainless steel • Needle and nozzle: Type 303 stainless steel