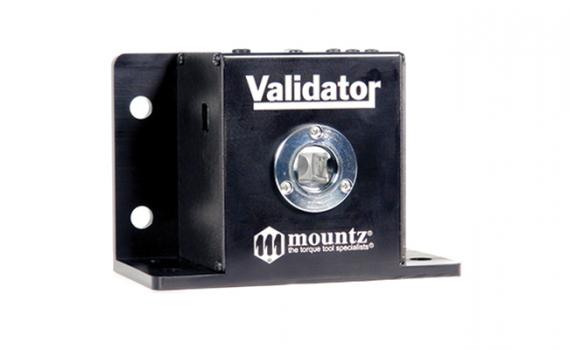

Economical Torque Wrench Tester

Description

A better way to validate torque wrenches instantly and efficiently is the Validator. It allows for instant verification that a wrench is still in calibration. Coupled with a torque wrench management and maintenance program the Validator can provide significant cost savings by not relying on a time-based calibration interval, but by servicing a wrench only when the wrench starts displaying the incorrect torque during in-house testing.

This tool is not suitable for power tools and it is ideal for checking torque tools on production floor daily or weekly to ensure the tools aren't falling out of calibration. Using a quality torque tester makes a safer world through accuracy and precision. Measuring torque is essential for companies to ensure their product’s quality, safety and reliability isn’t compromised. The failure of a three-cent fastener that isn’t properly tightened can lead to catastrophic or latent failures.

Specs

Features:

- Designed for testing and calibrating torque wrenches.

- Perform daily or weekly verification tests to confirm wrenches are operating at proper torque setting.

- Clockwise direction only.

- Selection of three operation modes: Peak, First Peak & Track

- Three units of torque measurements: (lbf.ft, N.m, kgf.m).

- Includes 9V Li-ion rechargeable battery and universal charger (100-240 VAC).

- Easy-to-use menu structure.

- LCD display.

- Small and lightweight.

- Built-in mounting plate provides flexibility for mounting options. Suitable to be placed within the assembly line area.

- Menu prompting calibration process.

- Features Go / No Go LED that illuminates when high or low tolerance setting is achieved or out of tolerance.