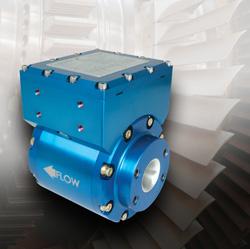

Gas Fuel Metering Valve for Large Turbines & Reciprocating Engines

Description

Precision Engine Controls Corporation, a leading designer and manufacturer of industrial and marine engine controls and services, introduces the eXVG, a next-generation gas fuel metering valve designed for use with large (up to10MW) turbines and reciprocating engines (up to 13,000 HP). The valve combines a patented fuel-flow measurement technique with fast, accurate and repeatable operation, resulting in better fuel/air ratio control for lowering emissions and improving engine performance, especially in Dry Low Emission (DLE / low NOX) applications. The eXVG’s optional 4-20mA interface allows complete closed-loop fuel control, and the unit’s onboard 24Vdc electronics provide improved health and data monitoring via an isolated RS-232 serial interface for downloading real-time data to the user’s laptop. Representing the latest advances in measurement, contamination resistance and precision control capability over a wide flow range, the eXVG’s two-inch diameter pipe effectively delivers 20% more fuel than the company’s highly successful XVG fuel valve, making the new valve ideal for larger engines or those operating with lower supply pressures or low BTU fuels. Design-wise, the rugged eXVG provides a single direct-acting solenoid actuator with no mechanical linkages and only one moving part. The valve’s balanced flow tube provides superior flow performance and assures smooth, fast operation over a wide pressure range. Featuring a contamination-resistant self-cleaning flow-through design, the eXVG also provides a fail-safe closing spring, with easy-to-clean soft seats, to ensure a positive shut-off. The eXVG’s standard 200:1 turn-down ratio allows operation over a wide flow range and low supply pressure, providing a four-fold improvement over the typical 50:1 turn down (max vs. min flow) of many competitive models. “We’re confident that the eXVG’s enhanced functionality will have a positive impact on the market by, among other things, reducing the need for redundant flow and temperature instrumentation,” said Joe Mares, PECC’s engineering manager for valves and actuators. “With several operational modes to choose from, the eXVG provides an integrated, cost-effective migration path from traditional, fixed-orifice solutions to better, lower-emission performance across the spectrum of larger turbine and reciprocating engine applications.” PECC’s unique measured-flow output provides an elegant way to measure flow without a sharp-edged orifice, turbine meter, coriolis meter or other independent direct-flow device. This patented approach employs a highly characterized orifice, sensors to determine the pressure across the orifice, a gas temperature sensor, and a carefully calibrated set of calculations that factors out sensor error to accurately determine real-time mass flow over a wide range of pressure, temperature and flow rates. Precise digital flow-characterization data is logged at the PECC test facility and downloaded to the valve itself, providing the eXVG with the equivalent of an extremely tight-tolerance orifice without the costs typically associated with high-accuracy machining. The eXVG’s onboard Digital Signal Processor (DSP) performs real-time mass flow calculations and compares the stored characterization information to the continuous measurement data supplied by internal gas temperature and pressure sensors, which in turn provides the user with a live analog feedback signal of mass flow.

Specs

• nput Voltage - 24 VDC • Minimum Voltage- 16 VDC • Maximum Voltage - 32 VDC • Steady State Current - 2 A typical / 3 A maximum • Peak Current - 5 A for 60 ms • Fuel Demand Analog Input: - Current 4 to 20 mA or Voltage 0 to 5 VDC • Fuel Flow Analog Feedback - Current 4 to 20 mA or Voltage 0 to ±5 VDC • Serial Interface - RS232 (isolated) • Bandwidth - 3 dB @ 10 Hz • Electrical Connections - 0.75 - 14 NPTF threaded conduit to 16-26 AWG terminal block w/grounding provisions • Fuel Media - Natural Gas or other man-made gases • Maximum Operating Pressure - 435 psig (30 Barg) • Proof Pressure - 1740 psig (120 Barg) • Minimum Controllable Flow- 0.1% of Maximum Fuel Flow • Maximum Controllable Flow - 8,000 pph at 300 psig • Leakage Flow - <1 pph • Flow Accuracy - ±3% of full scale • Linearity - ±1% of full scale • Step Response (10% to 90%) - < 100 ms • Dry Weight - < 38 lbs (17.2 Kg) • Temperature Limits - Ambient: -40°F (-40°C) to +200°F (93°C) • Fuel - -29°F (-20°C) to +257°F (125°C) • Weatherproof NEMA - 4 or IP65 • Vibration - Mil-std-810F, Method 514-5, Category 22 (5 to 2000 Hz) • Shock - Mil-std-810F, Method 516.5, Procedure 1, (20 G peak, 11 ms duration) • Humidity - Mil-std-810F, Method 507.4 (95% Relative, Non-condensing) • EMC - Per 89/336/EEC European EMC Directive • Certifications - CSA (Canada and US): Class I, Division 1, Groups B, C and D; T4 • Housing - 6061-T6 Anodized Aluminum • Wetted Components - 300 Series Stainless Steel NACE MR0175 Compliant • Seals - PTFE and Viton®