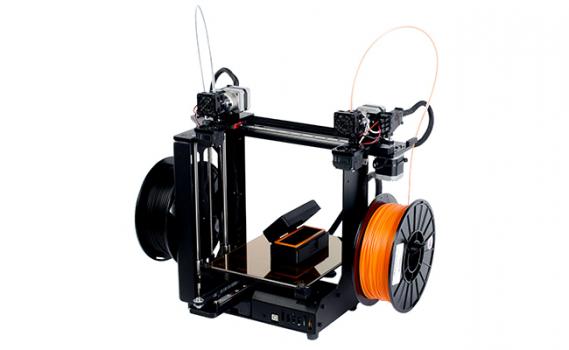

Independent Dual 3D Printer

Description

For highly accurate, high resolution prototyping and production jobs, even in an industrial setting, bet on this dual extruder desktop printer. Using two modular extruders means you get twice the throughput and can use two different materials on a build volume of 100 X 254 X 203 mm. This allows you to infuse flexible and rigid elements to your build, with at least 13 different materials to combine, ranging from ABS to carbon fiber. The previous M2 was named the world's #1 ranked Workhorse 3D printer, so you know this 29-lb. thoroughbred will race to a quick ROI.

Specs

Independent dual extruders: Achieve faster, more reliable multi-material printing and cut production time in half with single-material parts.

Print with unlimited complexity: Use soluble PVA and HIPS support materials. Combine flexible and rigid elements into a single part to achieve your desired mechanical, thermal, and chemical properties. Print multi-colored objects with stunning precision.

Wifi connectivity offering remote control and monitoring capabilities.

Onboard computer with 10+ GB storage.

OctoPrint for MakerGear control interface with access to features like one-click file preparation and direct design-to-print integrations.

Compatibility with a wide range of operating systems, devices, and browsers, including Windows/Mac/Lunux, iOS/Android, Chrome/Firefox/Safari.

Includes:

- MakerGear M3-ID 3D Printer with V4 Hot Ends

- Simplify3D 4.0 software license

- Power Supply with Adjustable Input Voltage (115 V or 230 V)

- Power Cord compliant with your country's power outlets

- Two 1 kg Spools of PLA (black and blue)

- 8 inch x 10 inch Borosilicate Glass print surface with applied film print surface

- Tool Set

- Sample print

- User Guide