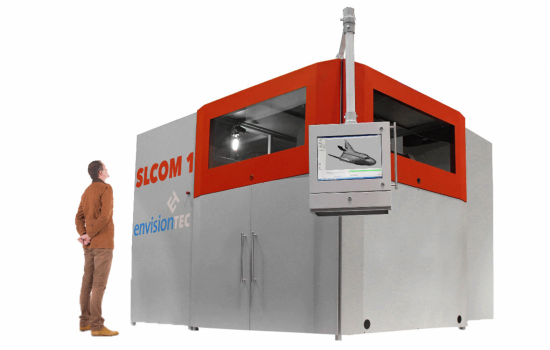

Industrial Scale 3D Printer Produces Woven Fiber Composite Parts

Description

EnvisionTEC's SLCOM 1 industrial composite 3D printer employs a new patent pending process known as Selective Lamination Composite Object Manufacturing that builds composite parts using layer-by-layer laminated thermoplastic composite fabric sheets from a roll. As the first 3D printer employing this technology, the SLCOM 1 will be capable of building objects up to 24” x 30” with a 24” height.

The SLCOM 1 can process a wide range of custom made thermoplastic reinforced unidirectional or multidirectional woven fibers tailored to the customer performance needs. Some of the composite matrix materials the SLCOM 1 can process include woven glass fiber, woven carbon fiber, or other woven aramid fibers reinforced with a choice of Nylon 6, Nylon 11, Nylon 12, Peek, Pekk, Polycarbonate, and many others. This allows for customization in delivering high quality 3D printed parts suitable for use in aerospace, automotive, consumer products, sporting goods, and potential applications in the medical space. The composites can be tailored for exceptional toughness, environmental resistance, vibration dampening, low flammability characteristics, high wear resistance and high strength to weight ratio.

Specs

- Build Envelope: 30 x 24 x 24 in.

- Accuracy: +/- 100 microns in X and Y

- Cutting Speed: Up to 20 inches per second linear speed

- Min/Max Layer Thickness: 0.1 mm to 1.0 mm (prior to lamination)

- Build Speed: Post lamination layer thickness dependent

- Material: UNI and Bidirectional Thermoplastic Pre-pregs

- Cutting Gantry: 4 Full AXIS cutting Gantry system (XYZR)

- Footprint: 125”H x 156” W x 93” D