Inspection Software for Machine Tools

Description

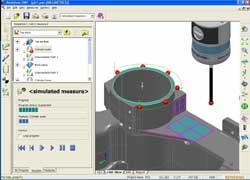

Renishaw makes it easy to gain the full advantages of on-machine probing with new PC-based inspection software for machine tools. The On Machine Verification (OMV) software is specifically written for machine tool inspection of prototypes, complex and large parts, multi-operation parts, and die & mould parts, employing original CAD data. The OMV enables off-line programming and graphical simulation of inspection routines without specialized programming or probing knowledge, using the CAD model. Programmed part inspection and measurement can improve process efficiency, integrate inspection and machining for greater process automation, and speed part throughput. With a straightforward point-and-click approach, inspection could not be simpler. By clicking various features on the modeled part, the inspection path is automatically generated. Using Renishaw non-lobing, high accuracy spindle probes — such as the new compact OMP400 or the established MP700 probe — surface data is measured and sent to the PC, where powerful (CMM style) measurement algorithms process the data. Features such as multi-point circles, cylinders, cones, spheres and planes can now be measured to a high degree of accuracy. The MP700 and OMP400 probes do not have to be calibrated in all the vectors in which they are to be used. This reduces the number of points required to measure each part, giving significant cycle time improvements. The OMV software produces clear and detailed graphical reports with live data capture to the PC for instant feedback on part quality. Data can be displayed graphically against the CAD part model and views rotated to various orientations. The software not only displays the measured deviations on the CAD model, but also represents errors with colored dots. These dots indicate whether the point is in, above or below tolerance and can be used to produce a ‘color map’ of the accuracy of the component. Renishaw OMV is able to ‘best fit’ groups of measured data to the model, reducing the deviations and errors by removing alignment and datum constraints. The data can be constrained in the X, Y or Z axis, 2D plane or in rotation only. Powerful tolerance inspection reports provide formal documentation of the component’s geometry, which can be combined with views of the CAD model. Native CAD files that can be used with Renishaw OMV include Auto CAD’s DXF & DWG formats, Catia, SDRC, Unigraphics and Pro/Engineer, as well as the standard formats of IGES, Parasolid, STEP and STL. Renishaw OMV is capable of running on a range of machine tools fitted with Fanuc, Mazak ISO, Pro3, Yasnac, Hitachi Seikos, Mitsubishi, Siemens & Heidenhain controllers. Renishaw OMV inspection allows machining operations to detect errors earlier and correct them before the parts are removed from the machine tool. The ability to check that the part is meeting specification at various stages of the manufacturing process can reduce the amount of scrapped components, particularly on complex, high-value parts. Probing can be used for final part buy-off inspection, eliminating post-process inspection for faster throughput and lean manufacturing benefits. For more information on the new OMV inspection probe software and Renishaw machine tool probes, contact Dave Bozich, Product Manager – Machine Tool Probes, Tel: 847-286-9953. Fax: 847-285-9974. Email: [email protected]