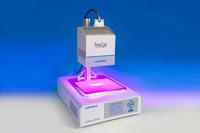

BlueWave LED Flood Curing System

Description

The BlueWave LED Flood Curing System offers high intensity and uniformity, enabling fast and repeatable cure times. The system is available with three different wavelengths LED arrays (365, 385, and 405 nm) so users can fully optimize the curing process between their light-curable material and the curing system.

The BlueWave LED features a 5 x 5 in. (12.7 x 12.7 cm) active area for curing larger parts and for helping to reduce cure times. The instant on/off capability of the LEDs eliminates the need for mechanical shutter components and lengthy warm-up times but provides faster exposure cycles and lower maintenance costs. It is CE certified, RoHS compliant, and offers user-friendly operation, making this flood unit the ideal curing system for manufacturers looking to complement their “green” initiatives.

Specs

| Typical Initial Output Intensities** | PrimeCure - 850 mW/cm² |

|---|---|

| VisiCure - 950 mW/cm² | |

| RediCure - 450 mW/cm² | |

| Curing Area | 5 x 5 in. (127 x 127 mm) |

| Irradiator Head Dimensions, W x H x D | 6.38 x 4.48 x 5.79 in. (162 x 190 x 147 mm) |

| Weight | 8 lb. (3.63 kg) Irradiator |

| 15 lb. (6.80 kg) Controller | |

| Power Supply Dimensions, W x H x D | 13 x 4.5 x 18.25 in. (330 x 114 x 464 mm) |

| Static Uniformity | PrimeCure - 0.35 |

| VisiCure - 0.4 | |

| RediCure - 0.4 | |

| Cooling/Temperature Management | Air cooled |

| Power Requirements | 100 to 240V AC 50/60Hz (Auto-Ranging) |

| ** | When measured at 25mm distance with an ACCU-CAL 50-LED radiometer in Flood mode. |

- Larger curing area - 5 in x 5 in (12.7 cm x 12.7 cm) active area

- High-intensity LED (850 mW/cm² typical at 385 nm), (950 mW/cm² typical at 405 nm)

- Faster cure times

- Consistent frequency and intensity output for better process control

- Longer life than conventional arc lamps

- Intensity is adjustable for specific applications

- Greener technology

- Mercury-free, environmentally-friendly LED

- No hazardous waste disposal requirements

- No ozone generation

- Lower energy consumption than conventional curing lamps

- Instant on/off

- No warm-up period

- More energy efficient

- Shutter-free design

- Reliable operation with lower maintenance costs (no moving parts)

- LED flood array available in 365, 385, and 405 nm wavelength options

- Compatible with a variety of UV and visible light-curable materials

- Wavelength flexibility allows co-optimization of adhesive and curing system for optimal cure

- Self-contained, lightweight LED flood array with cable interface and PLC port

- Flexibility to use as a bench-top cure system or mount the LED flood array remotely from the power supply for automated process equipment or conveyor integration

- Flexible system with a full line of accessories