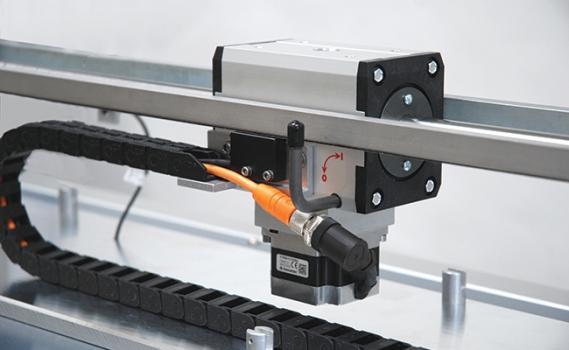

Linear Motion Drive

Description

The Precision Motion Drive System is a Uhing Model RG rolling ring linear drive integrated with a motion controller for precision linear motion applications. The Precision Motion Drive is fully programmable and meets application requirements for precision winding/spooling, pick-and-place machines, X-Y coordinate tool movement, metrology equipment and other machinery providing fast, accurate positioning and reciprocating linear motion. Depending on the size of the RG drive nut in the system, the Precision Motion Drive System provides from 7 to 800 pounds of axial thrust.

The linear movement of the drive head is controlled via software and monitored by sensors feeding back to an electronic control unit. The Precision Motion Drive stores up to 20 programs which may be recalled at the touch of a button. While meeting application requirements for most precision linear movement applications, the system is especially well suited for precision winding of a wide range of round or flat materials including wire/cable, PVC tubing, string, fiber, rope, rubber hose and vinyl strips. The Precision Motion Drive system also handles custom winding patterns and irregularly shaped spools.

The Precision Motion Drive System offers virtually unlimited flexibility with regard to customized linear movement of the drive nut. Stop/start, travel direction, linear pitch, travel speed, repetitive processes, ramp up/down and essentially all other variables pertaining to drive nut movement may be programed into the system to meet precision linear motion application requirements. The core PLC/software package may be used to control multiple Uhing Model RG drive stations making it unnecessary to invest in multiple systems to help sustain high production rates.

A stepper motor controlled by a Siemens S7 PLC is included in the package. Fast, simple operation is enhanced with intuitive prompts displayed on a touch screen control panel. The shaft on which the Precision Motion Drive runs is smooth case-hardened steel. There are no threads which makes the system useful in applications where particulate contaminants could fall into threads causing jams or clogs. The shaft rotates in one direction only making it unnecessary to purchase a reversible motor. Drive nut travel direction, linear pitch and other motion parameters are controlled by the angle of the rolling ring bearings inside the drive unit which in turn is controlled by user programming.