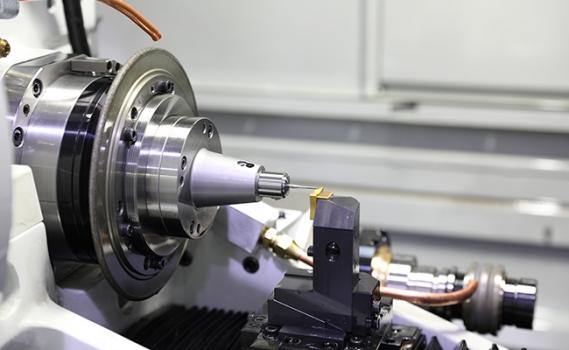

Rigorous CNC Grinding

Description

ANCA is well known for providing innovative products to the market. IMTS 2018 will be no exception with the first preview of the latest addition to their machine range. It has been designed in response to customer requests to provide a full range of products to meet all grinding requirements. Complementing the FX, MX and TX range, this brand-new machine adds a new dimension of productivity to shop operations.

Industry 4.0 with ANCA - ToolRoom software focuses on manufacturing the most complex tool geometries of the future with the perfect balance

ANCA ToolRoom 2019 version helps design and manufacture complex tool geometries and getting them balanced perfectly for optimal cutting conditions.

New at the show is endmill cycles for ballnose and corner radius, tool balancing and next generation fluting cycles. Launched earlier this year, ANCA’s new Management Suite, either onsite or in the cloud is a game changer for the CNC grinding industry, according to ANCA. It provides customers the technology to monitor the performance of their machines no matter where they are in the world. The new software also enables companies to run smart factories by providing live production information to make data-based decisions on operational improvements.

The latest version of ANCA ToolDraft can create tool and wheel pack drawings within minutes. The CIM3D V8.2 will show how you can get the right balance for variable helix or variable index tools for high speed machining.

TapXmicro: Single setup grinding of micro taps 3mm and under

Grinding micro tolerances with superior quality the TapXmicro delivers superior quality achieving a pitch diameter CpK of 1.5 when batch grinding M1.4 x 0.3mm taps with a tolerance of ±7μm.

When thinking of applications for micro taps (typically defined as having thread pitch of 0.3mm or less) people tend to think of watch making or jewellery industries, but the applications is much broader. In fact, items within arm’s reach – consumer electronics, smart phones and wearables now drive the massive volumes of micro taps and we want our customers to make the most out of this opportunity.

The TapXmicro is a logical extension of ANCA tap grinding capabilities, giving customers a fast return on investment with the versatility to grind taps up to M3. Based off ANCA’s proven MX Linear machine platform, the 5-five axis machine includes all the necessary features to support each grinding operation. It has capacity for up to six wheel packs, dressers for all grinding wheels, and a flexible compensating chuck system between center work holding.

Feature-packed grinding expert: the MX7 Linear

The popular MX7 Linear is a powerful versatile, next-generation CNC grinding machine designed to meet the rigorous demands of production grinding. A hardworking, high productivity system, its unique features make it capable of handling varied batch sizes with minimum set up time. The MX7 Linear is driven by LinX cylindrical linear motors (on the X & Y axes) which provide greater performance, higher feed rates and a superior surface finish on the ground tool. The machine will also be demonstrating the FastLoad-MX, a reliable, cost-effective tool loader designed to enhance the productivity of the MX range of machines.

The following features greatly improve grinding capabilities:

- LaserPlus

- Auto Wheel Qualification

- Motorised Dresser

- AutoStick (4 station)

- Steady Bed & Popup

FX7 Linear is a great solution on a budget

The FX7 Linear at IMTS will have a range of automation options to maximize any user’s tool production. On display will be the optional Fanuc robot tool loader and 6 station wheel changer (includes changing of coolant manifolds), allowing unmanned capacity for up to 1,092 tools. The LaserPlus option provides automatic laser tool measurement and compensation to maintain a geometric tolerance of +/-0.002mm over small or large tool batches. There will be a dry-cycle tool production demo of compression routers (up/down cutters), which the LaserPlus is ideal for as it measures the OD for each of the up cutter and down cutter sections, guaranteeing tool accuracy for both manufacturing and regrind applications.

All the machine options are contained within the compact machine footprint, so there is no need for extra floorspace. The FX7 Linear and its options:

- Fanuc tool loader (with 6 station wheel changer)

- LaserPlus

- iView Camera

- Auto Wheel Qualification

- AutoStick

- Pop-up Steady

- Premier B32/45 Precision Collet Adaptor

ANCA’s LinX cylindrical linear motor ensures rigidity to deliver a surface finish roughness average as low as 0.16 Ra

As well as being pleasing to the eye, highly polished flutes and gash surfaces improve chip evacuation and significantly improve tool performance and life. The smoother surface enables swarf (or chips) to exit more freely, preventing chip packing and material build up during machining.

ANCA is well known in the industry for its rigid grinding machines and has combined this with its sister company, ANCA Motion’s, LinX linear motor technology. Tools ground on our machines have a consistently high-quality cutting edge and surface finish. Since the product was launched customers have reported dramatically better results using the duel technologies.

ANCA is the only large tool grinding manufacturer to offer this type of technology on every machine in its range.

An Alicona infinite focus XL metrology machine in ANCA’s Grinding Centre of Excellence was used to verify the results to Nano metre accuracy finding that a surface finish roughness average as low as 164.7nm (which translates to 0.16 Ra) was achieved. The LinX cylindrical linear motors ensure there is no loss of preload or rigidity when grinding tools. As well as that, reversal errors are eliminated and higher contouring accuracy can be maintained due to a control algorithm we use which is unique to ANCA.

Tools with highly polished surfaces means better cutting edges which will ensure extended tool life and improve the finish on the machined part. We have seen the demand for tools with a superior surface finish continue to increase and cutting tool manufacturers are producing more highly polished tools in larger quantities.