3D Printer For Small Serial Production

Description

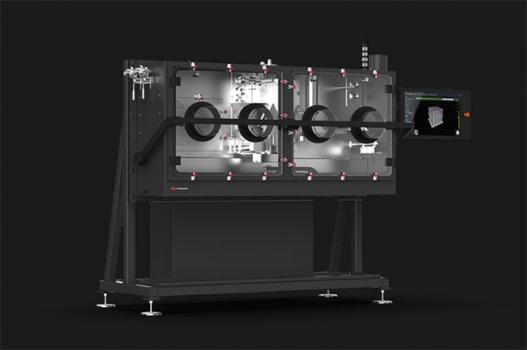

Designed to serve as a bridge from process development to full-scale mass production of end-use metal parts, the P-1 printer leverages Single Pass Jetting (SPJ) technology and core additive manufacturing benefits for serial production.

The P-1 offers enhanced process flexibility and features a state-of-the-art print bar with native 1,200 dpi, advanced printhead technology that supports a wide variety of binders, and an inert processing environment to support both non-reactive and reactive materials.

SPJ technology on the P-1 is designed to print each layer in less than three seconds, including powder deposition, powder compaction, anti-ballistics, binder deposition, and printhead cleaning. At this maximum build rate, the P-1 can achieve production throughputs 10 times higher than those of legacy PBF systems and fast enough to complete a full build in less than one hour. The P-1’s open material platform and inert process environment allow customers to use low-cost, third-party metal injection molding powders across a variety of materials, making the P-1 suitable for cost-effective serial production of small and complex parts in addition to smaller-scale process development activities. Powder reclaimed during the printing and depowdering process can be recycled for future use, driving further cost efficiencies and resulting in a more environmentally friendly manufacturing process. In addition, the tooling-free manufacturing process on the P-1 facilitates quick turnovers to new jobs along with the ability to print many complex geometries simultaneously with no print supports required.

P-1 customers will also gain access to Desktop Metal’s Fabricate manufacturing build preparation software, as well as to the Company’s newly-released Live Sinter application, which dynamically simulates the sintering process and automatically generates print-ready geometries that compensate for the shrinkage and distortion that take place during sintering, minimizing process trial and error while improving accuracy.

Specs

Print Technology | Single Pass Jetting |

Print direction | Uni-directional |

Build box size | 200 x 100 x 40 mm (7.9 x 3.9 x 1.6 in.) |

Resolution | Native 1,200 dpi |

Max build rate (65 micron layer thickness) | 1,350 cc/hr (82 cu in/hr) |

External dimensions | 1.8 x 2.0 x 1.2 m (70 x 79 x 45 in.) |