A New Revolution in Turning: PrimeTurning

Description

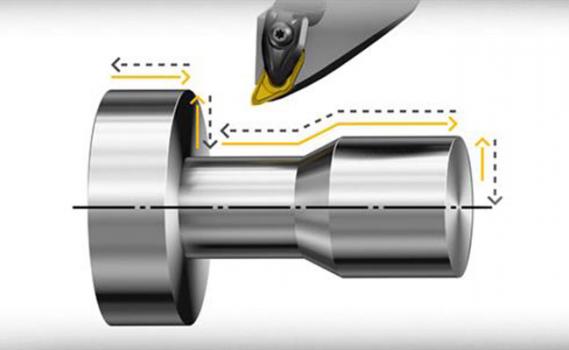

PrimeTurning enables operators to turn in all directions in a much more efficient and productive way as compared to conventional turning.

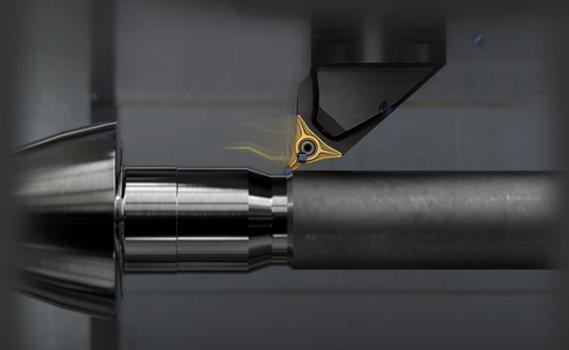

The PrimeTurning method enables turning away from the shoulder, eliminating the possibility of chip jamming commonly observed in conventional turning. This results in an excellent surface finish and avoids tool damage.

This concept comprises a new turning method, dedicated CoroTurn Prime tools, and a code generator.

CoroTurn Prime inserts have three edges per corner. One edge each for longitudinal, facing, and profiling, distributing the wear over a longer edge and not just the insert tip. It also moves heat away from the cutting zone, helping inserts last substantially longer.

The small entering angle (KAPR) will create a thin and wide chip, which spreads the load and heat away from the nose radius. This results in increased tool life or allows for increasing cutting data.

Longer lasting inserts avoid tool changes under long tool paths, dramatically reducing the cycle time.

Secure maximum output with the PrimeTurning code generator that supplies programming codes and techniques to set up proper parameters and variables for a particular application.

PrimeTurning offers a more than 50% productivity increase as compared to conventional turning.

Specs

- >50% productivity increase

- Flexibility to do turning in all directions

- Longer lasting inserts

- Faster metal removal rates mean more parts per run by doubling the speed and feed

- Extremely fast return on investment, higher productivity, and less capital expenses result in a lower overall cost per component.

- Higher machine utilization and less time with setup and tool changes

- Small entering angles