Multisensor Measurement Machines

Description

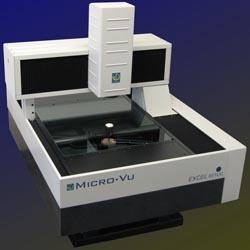

Micro-Vu Corporation has introduced its new Excel 650 series of multisensor measurement machines with ten new models that accommodate large parts or multiple smaller parts for three dimensional measurement. The systems feature high speed, high accuracy measurement using new optics, new laser capabilities, a substantial granite base, closed loop motion control, and high resolution encoders. With the large 650x650mm XY capacity, the machines accommodate large parts up to 100kg on the glass. Machines feature larger Z capacities of 160mm, 250mm, and 400mm. The machines use a gantry stage design allowing parts to remain stationary while the XYZ movement of the sensors takes place above the parts.

The Excel 650 Series machines include Micro-Vu's InSpec Metrology Software. InSpec integrates 36:1 zoom, laser, touch probe sensor, rotary indexer, and platen capabilities with camera based vision measuring capabilities. InSpec includes proprietary correction and vision algorithms that give machines sub-micron capabilities. The software has set the standard for ease-of-use among vision and multisensor measurement machines. It is now used around the world in 15 languages.

An important design goal was to reduce costs through concurrent engineering. Micro-Vu has reduced material and machining costs by designed parts specifically for its 5 and 6 axis machining centers. With lower production costs, Micro-Vu is able to offer new Excel 650 systems for under $50,000. The new Excel machines are competitive in price with machines that have only a quarter of the capacity.

The Excel 650 Series machines include Micro-Vu's InSpec Metrology Software. InSpec integrates 36:1 zoom, laser, touch probe sensor, rotary indexer, and platen capabilities with camera based vision measuring capabilities. InSpec includes proprietary correction and vision algorithms that give machines sub-micron capabilities. The software has set the standard for ease-of-use among vision and multisensor measurement machines. It is now used around the world in 15 languages.

An important design goal was to reduce costs through concurrent engineering. Micro-Vu has reduced material and machining costs by designed parts specifically for its 5 and 6 axis machining centers. With lower production costs, Micro-Vu is able to offer new Excel 650 systems for under $50,000. The new Excel machines are competitive in price with machines that have only a quarter of the capacity.