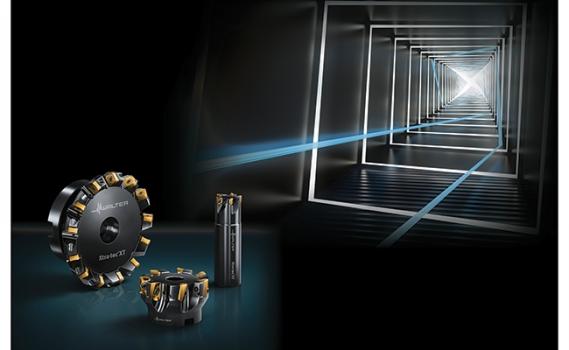

Next Generation Milling Tools

Description

Xtra·tec XT (Xtended Technology) milling series is designed to achieve increased productivity and process reliability. This new generation of milling cutters is being launched with initial offerings of shoulder milling cutters and a face milling cutter. The mills cover virtually all requirements in shoulder and slot milling in all common material groups.

The key design feature of these tools is the position of the indexable inserts, which is at a greater incline and with a larger contact surface. This reduces the surface pressure in the seat while increasing stability. Their larger screw hole cross-section stabilizes the indexable insert, and the longer screws hold it in place more securely. The cutter body has also been made more stable, as it now has more material behind the insert seat.

Along with greater process reliability, the position of the indexable inserts also allows for the addition of an extra tooth, thereby increasing productivity. The precise 90-deg. shape of the shoulder milling cutters helps reduce the need for additional finishing operations. The clamping screws, which are easier to access, optimize handling.

Another significant feature is the smaller indexable inserts that can be fitted to the Xtra·tec XT milling cutters, continuing today’s trend towards reduced machining allowances. This applies especially to the Xtra·tec XT M5009 face milling cutter, which combines small depths of cut with the advantages of the double-sided Walter Tiger·tec indexable inserts. These inserts have eight useable cutting edges instead of the usual four providing increased efficiency plus fewer required finishing operations.

Specs

- Maximum stability, maximum productivity

- No need for additional finishing operations

- Universal use

- Indexable inserts in Tiger·tec Silver and Tiger·tec Gold