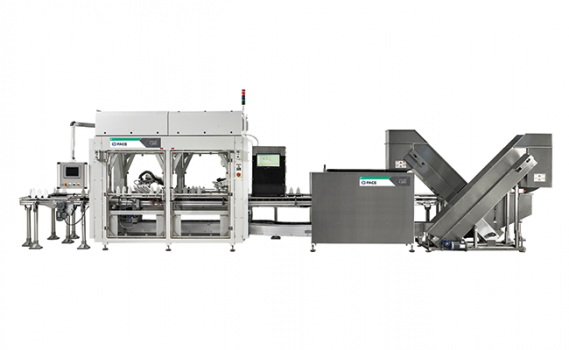

Robotic Unscrambler Orientor

Description

Pace Packaging, a ProMach product brand, introduces its R-Line robotic bottle unscrambler orientor designed for plastic containers that require puck handling. The innovative R-Line system achieves speeds up to 240 bpm with two robotic cells.

The system includes a bulk hopper, elevator and bottle alignment station that feeds bottles onto multiple lanes in either base-leading or neck-leading positions, followed by a camera and two ABB robotic cells. The R-Line unscrambles, orients and inserts empty containers into pucks for improved container handling through the production process. The R-Line can also easily place containers directly on the conveyor if needed.

With up to eight lanes, Pace’s flexible multi-lane system can satisfy virtually every application. Feeding aligned containers enable R-Line to achieve speeds of up to 240 bpm with only two robotic cells. Compared to other robotic unscramblers that use up to six robots to achieve similar speeds, R-Line offers a footprint that is up to 30 percent smaller.

R-Line handles HDPE and PET containers of any shape, with or without handles, from 8 to 32 oz (226 to 908 g) in size. Gentle container handling and soft end-of-arm tooling prevent scuffs, scratches, and abrasions to keep plastic bottles pristine.

Container changeovers can easily be accomplished in less than two minutes on R-Line with no change parts and no tools required for most applications thanks to universal end-of-arm tooling from ProMach Performance Services. To ease the operation and ensure consistent performance when starting up a new container, no mechanical adjustments are needed – simply select the recipe on the touchscreen control panel and all settings are automatically changed, including lane widths. R-Line can be equipped with either Allen-Bradley or Siemens controls.

The system is virtually maintenance-free, offering a very low cost of ownership. R-Line is supported worldwide by a dedicated team of Pace Packaging and ProMach Performance Services technicians.

Specs

- Two-robot configuration delivers speeds up to 240 cpm – Innovative multi-lane container infeed system enables R-Line systems to do the work of up to six robots required by competitive systems

- Virtually unlimited container compatibility – R-Line unscrambler orientors can run a virtually unlimited variety of containers with and without handles from 8 fl. oz. (236mL) to 32 fl. oz. (946 mL)

- Versatile operation - System capable of inserting containers into pucks or placing them directly onto the conveyor

- Universal end-of-arm tooling – R-Line end-of arm tooling features a universal design that accommodates a virtually unlimited range of container styles, shapes and types

- Fast, push-button, recipe-driven changeovers – Container changeovers are completed via the HMI in two minutes or less; universal end-of-arm tooling does not need to be removed and replaced as part of the changeover process

- Scuff & scratch-free container handling – Bottle infeed system and universal end-of-arm tooling are designed to prevent and eliminate scuffs and scratches Space-efficient, linear technology and footprint – Uses up to 30 % less floor space than competitive systems requiring three or more robots