SPRING Technologies Ushers in Industry 4.0

Description

SPRING Technologies will show visitors at IMTS 2016 how its “NCSIMUL SOLUTIONS 10” all-in-one digital suite can truly usher in the “smart” factory.

In Booth E-3267, the company is focusing on its most popular modules in the suite – NCSIMUL MACHINE and NCSIMUL CAM.

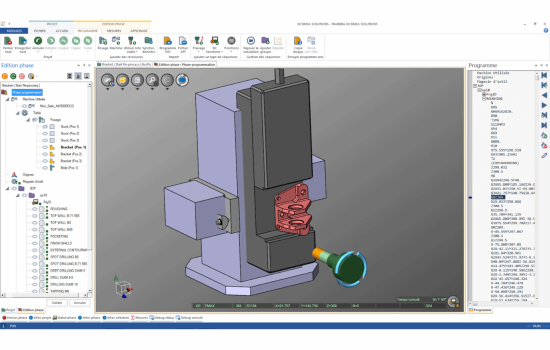

NCSIMUL MACHINE:

NCSIMUL MACHINE is an innovative CNC software solution providing realistic simulation of the machining process. Users can simulate, verify, optimize and review machine programs based on the actual characteristics of the machine tools. Three-dimensional graphics help to avoid machining crashes while powerful algorithms and embedded process-based knowledge enable cutting conditions to be optimized.

NCSIMUL MACHINE verifies programs in three steps: investigates and corrects coding errors, simulates to locate collisions and correct motion errors, and validates the program. The benefits are many, including reducing the time spent on debugging programs; preventing the costly risk of spindle collision, tool breakage and scrap; and improving cycle times and process optimization efficiencies.

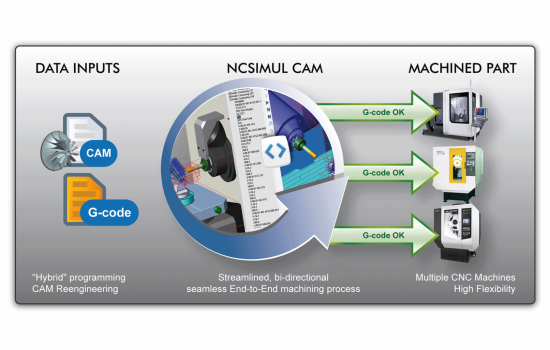

NCSIMUL CAM:

This module streamlines the existing CAM process to simplify CNC programming. It allows users to change, in one click, the target machine without any reprogramming efforts. From the main CAD/CAM program or machine controller G-code, NCSIMUL CAM generates programs for any machine tool that are verified and optimized without an external post-processor. It takes into account the kinematics of the machine tool, machine controller, cutting tools and conditions. This efficiency results in lead-time reduction from prototype to production and in repurposing legacy programs to new machines.

Specs

Booth E-3267

NCSIMUL MACHINE:

- Test your program on a PC; keep your CNC machine running

- Eliminate manual prove-outs

- Secure your machine environment and avoid crashes

- Train new employees in shorter virtual sessions and eliminate risk

- Optimize cutting conditions and improve productivity

- Standardize shop floor documentation

- Collaborate with your internal team, suppliers and customers

NCSIMUL CAM

- Generate automatically new CNC machine programs from a formally created CNC toolpath

- Switch your part machining between the different CNC's, on-the-fly, without reprogramming

- Reuse existing APT or G-code files with just a copy/paste click, to optimize the manufacturing process

- Eliminate external postprocessors thanks to the integrated CNC processor

- Connections between machine sequences are automatically calculated in an optimal way