Strategies for Low Risk Sourcing in a Constrained Market

Description

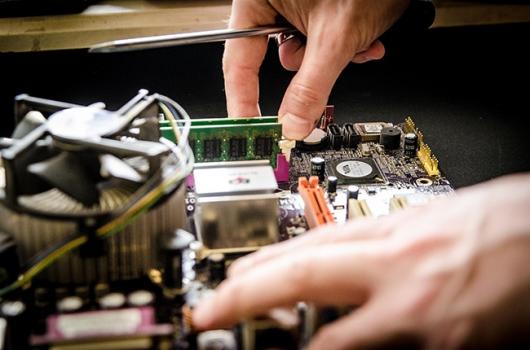

Direct sourcing of electronic components used to be pretty simple. An OEM or Electronic Manufacturing Service (EMS) provider would order direct from the manufacturer or through authorized distributors to obtain any required components.

Today, the challenges of a highly stressed supply chain are forcing many OEMs and EMS providers to rethink the way they source components. With parts such as multi-layer ceramic capacitors (MLCCs) and other low-cost components in chronic shortage with extended lead times for delivery, manufacturers must be able to get these parts on-time at the lowest possible cost without assuming additional risk.

As a result, many are turning to independent or hybrid distributors for long lead-time parts.

“For U.S. manufacturers there has been harmony in the supply chain for most of the past decade, so the need to identify alternative suppliers has not been as pressing as it is now,” says Mike Thomas, vice president, and global general manager at Classic Components, an independent distributor based in Torrance, CA.

Know Your Source

According to Thomas, the mantra in his industry to eliminate risk is to “know your source.” To accomplish this, leading independent distributors invest millions to manage global supply networks, rate/prioritize suppliers, establish preferred supplier relationships and acquire the latest inspection equipment and utilize effective Quality Management Systems (QMS).

Purchasing Power

The truth is that many of the shortages were predicted some time ago. As a result, leading independent stocking distributors like Classic Components have spent the past few years engaged in a long-term strategy of identifying, and investing in, directly sourced critical electronic components.

Global Networks

Another direct source for high demand parts comes from tapping into a large global network. Because of the worldwide demand for components, independent distributors have expanded globally and placed sourcing experts in key supply markets.

Rigorous Vetting

Another way to ensure the reliability of the independent distributor is to ensure they are thoroughly vetted. Established companies are used to complying with frequent requests for audits. In fact, some of the robustness of the quality systems implemented by independent distributors can be attributed to this activity.

Continuing Shortages

Through investment in developing deep global networks, inspection, authentication, inspection, and quality systems, independent stocking distributors stand ready to provide OEMs and EMS providers a robust option to navigate the white waters of international supply nimbly, effectively, and without the risk.