Wireless Charging Protection System

Description

Whether aircraft parts, car bodies or ship propellers—in industry, heavy loads are often transported automatically to processing stations by automated guided vehicles (AGVs) or floor conveyor vehicles (FCVs). Intelligent inductive charging technology is needed to operate these systems efficiently. With its Wireless Charging Protection System (WCPS), the PUK Group is launching a charging protection infrastructure that delivers safe contactless power transmission even in demanding environments.

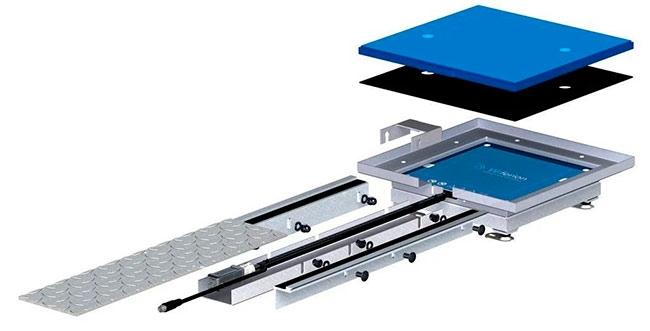

Cable routing experts at the PUK Group, in partnership with Wiferion, have developed the WCPS charging protection infrastructure for the etaLINK inductive battery charging system. WCPS is a coordinated system for the special requirements of modern industrial electric vehicles that protects the charging electronics from environmental influences. Its robust design and flush-floor integration make the solution particularly suitable for environments with intensive load cycling.

The patented etaLINK 3000 system was developed for inductive charging of industrial vehicles within the area of mobile robotics and wireless charging AGV. With this design, the chargers take into account the intelligence and autonomy of the new generation of robotics systems. They can be easily and independently installed and provide the vehicle with all relevant data. The absence of mechanical charging contacts makes it easy to integrate charging the battery into existing processes and thus an intermediate charge of the batteries is possible. This saves time and eliminates the potential dangers posed by open contacts. The etaLINK charging systems are maintenance-free and enable uninterrupted operation over many years. Furthermore, the inductive charger works with any type of battery.

The charging technology from Wiferion consists of a stationary transmitter unit with wallbox and charging pad as well as receiving electronics, which is installed in the AGVs and FFZ by plug & play. If a vehicle drives on or next to the charging station, the charging process begins in less than a second. It does not matter from which direction the charging station is approached. An integrated CAN interface transmits data on the battery status and energy level to the fleet management. etaLINK 3000, like the etaLINK 12000 system, is compatible with all available battery systems.

WCPS is a charging protection enclosure system that serves as a functional extension of PUK’s cable routing systems, combining tested functionality, and optimum usability. The system consists of two components: the infinitely adjustable charging protection housing, which accommodates the charging pad, and the heavy-duty duct, which reliably protects the cable. Both units are connected via a quick connector. Visible or concealed cable routing variants are possible. Further flexibility is provided by the ability to retrofit the system in existing environments with minimal intervention in the existing structure. The protective cover is made of a heavy-duty and very thin PCX material, ensuring extremely high resistance to pressure, impact, and shock. The maximum load capacity of the system is 15 kN. The WCPS is designed for retrofitting industrial buildings, but can also be easily integrated into new construction projects with an additional formwork body.

Specs

| Continuous charging power | 3,000 W |

| Charging voltage | 15 to 60 V |

| Charging current | 60 A |

| Protection class | IP65 and IP68 |

| Optimum distance | 15 to 40 mm |

| Position tolerance | +/– 30 mm |

Features:

- etaLINK achieves an efficiency of up to 93% during the transfer of energy.

- The charging process begins within 1 second.

- The system complies with the IP65 & IP68 protection class, making it suitable for use outdoors and in harsh environments.

- AGVs and other logistics vehicles can simply be driven up to the charging pad from any direction and a high position tolerance is guaranteed.

- Thanks to their small dimensions, the mobile units can even be fitted into compact vehicles.

- Management, consumption, and telemetry data are transferred to the charging pads contactlessly via infrared interfaces, allowing the system to be digitally integrated into the logistics process.

- In-Process-Charging may reduce the amount of peak current provided by your energy supplier.

- One charging pad can be used by a vast number of different vehicles.

- Changes to building infrastructure and special charging areas are not necessary.

- Wear parts, damage caused by improper use and problems caused by contamination all become things of the past.