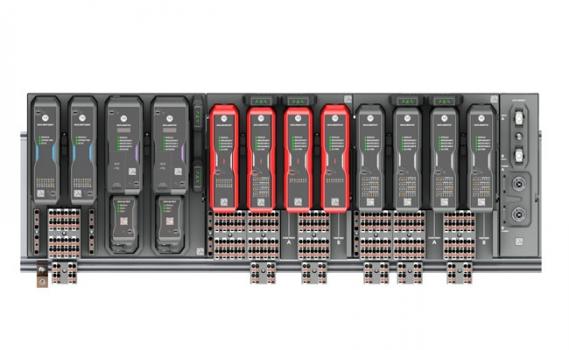

Allen-Bradley Bulletin 5015 FLEXHA 5000 I/O Modules

Description

2023 NED Innovation Award Finalist

Designed to be a smarter, more efficient I/O solution, the FLEXHA 5000 I/O family offers high availability and continued evolution of the PlantPAx Distributed Control System (DCS). With flexibility and reliability, it enables integrated control for the Connected Enterprise production system, decreasing TCO and enhancing productivity.

The FLEXHA 5000 I/O module helps reduce hardware complexity and cost by using an integrated design and enhances communication with 1 Gb EtherNet/IP network connectivity, offering higher speed and increased bandwidth.

With the range of options this platform offers, process customers can choose the I/O that best meets their operational needs. This solution reduces hardware complexity and cost by using a conveniently integrated design that minimizes downtime and commissioning time.

Using the platform with PlantPAx helps users achieve more efficient engineering time through tight integration with an instruction set in the PlantPAx system. The platform enables customers to optimize their footprint by allowing them to mount up to 24 I/O modules on a single node, vertically or horizontally, and in any module sequence. The modules contain a universal card option that allows for flexibility in I/O choice simplifying field wiring, reducing spare module requirements, and reducing maintenance time.

Specs

- Mount up to 24 I/O modules on a single node, vertically or horizontally, and in any module sequence

- Operate at -40 to 158°F(-40 to 70°C) and in extreme environments up to GX rating with conformal coating

- Use in hazardous areas under Class I, Division 2, Zone 2, and Groups A, B, C, D

- Reduce downtime with simplified Removal and Insertion Under Power (RIUP) and easy online changes

- Gain support for ControlLogix 5580 controller redundancy in high-availability applications from Studio 5000 Logix Designer software (version 35 or later)

- Reduce downtime with easy access to additional process diagnostics via HART Premier Integration in Studio 5000 Logix Designer software

- Save engineering time through tight integration with instruction set in the PlantPAx system

- Features a universal card option that allows for flexibility in I/O choice. This I/O choice is configurable per channel within Studio 5000 software (version 35 or later) as analog (HART capable) or discrete, input or output

- Available in simplex or duplex module configurations