Making Needle Point Grinding More Productive

Description

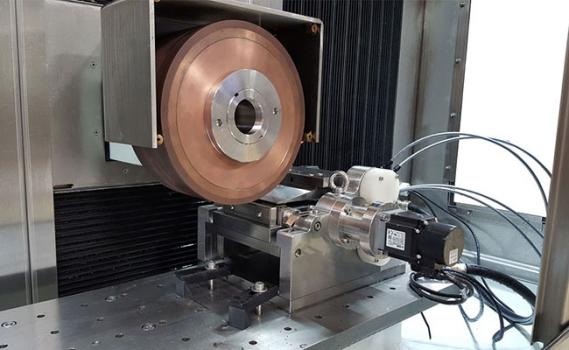

Electrochemical grinding (ECG) solutions provider Tridex Technology, a Glebar Company, recently delivered a process to a customer for needle point grinding using ECG and the Point Grinding System Model PGS-100.

Grinding sharp points onto needles can be a difficult process. In most cases, the parts must be taped for handling requiring additional steps in the production process. Many manufacturers still use converted OD grinders with soft grinding wheels and custom tooling. These grinding wheels wear at a high rate. Setting up and changing over these grinders takes a significant amount of time and requires extensive mechanical adjustments delaying production.

Once in production, these grinders leave a large ID burr requiring the needles to be sent through a secondary process such as grit blasting or electro-polishing. Complex needle points such as Menghini points require a separate primary bevel cut and secondary sharpening leading to longer cycle times.

Some custom machine builders have developed needle grinders using robots to replace or simplify the fixturing. While this approach looks innovative there are significant limitations in productivity and flexibility. A robotically controlled fixture requires a series of collets to clamp and rotate the parts in unison. Collet systems take up a lot of space and this limits the number of parts that can be sharpened to a fixed amount usually no more than 20 at a time. On a standard pointing fixture, the quantity per grind increases as the diameter gets smaller. Another limitation of a robotic fixture is that the needles must be held far from the grinding wheel allowing for deflection and inaccuracy. While robots have gotten better and more accurate, they will never approach the precision of properly designed moving platen pointing fixtures.

Tridex was challenged to deliver a highly accurate process that would eliminate taping, pre- and post-processing, deflection, allow for quick set-up and changeovers, and can handle all variety of points used in the industry.

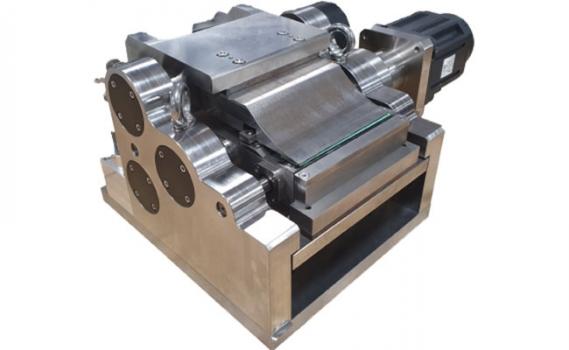

Tridex developed and produced its Burr Free Electrochemical Point Grinding System Model PGS-100 which works as an adjunct to the Tridex SG-1645 and SG-2060 electrochemical grinders. Both grinders are CE and ISO 13849 Certified ensuring safety for the operator and environment. The combination offers a fast set-up and fast changeover times. Using the ECG process, the PGS-100 is a fully programmable pointing and material handling system for medical device points on a tube or solid wire. It features a servo-controlled design for high precision rotation and repeatability. Simple tooling for loading and unloading allows any trained operator to run multiple machines at once. It is made from stainless steel making the point grinding system very robust and durable.

“The PGS-100 allows manufacturers to become more productive in their needle point grinding,” says Tom Travia, Vice President of Business Development at Glebar Company. “With the PGS100, there is no need for grit blasting or taping, eliminating an entire step from the production process. Part set up is programmable requiring no mechanical adjustments making changeovers between diameters and tip geometry easier and faster.”

The PGS-100 can produce any number of facets on needles measuring from 1/8 to 0.017-in. in diameter including Tri-bevel, back bevel, trocar, diamond point, stylet, Franseen, custom points, and Menghini (sharpened bevel) points. It is also capable of handling 4-in. (100 mm) width of workpieces holding between 32 to 120 needles depending on the diameter allowing manufacturers to maximize their output per cycle. By clamping the needles closer to the point, the PGS-100 allows for better accuracy and minimal deflection. The Tridex grinder is also capable of secondary operations such as burr-free cross slot grinding and notch cuts for biopsy needles.