EcoStruxure Automation Expert Makes Building Systems a Breeze

Description

2023 NED Innovation Award Finalist

EcoStruxure Automation Expert 23.0, a software-centric industrial automation system, Schneider Electric continues to add benefits targeting additional segments by offering the first software-based redundant automation solution on industrial PC (IPC) platforms for markets that require redundancy, such as desalination. It minimizes downtime and production loss across plants with control and network systems that keep processes running even in the case of a single fault.

New features in V23.0 include enhanced integration with the AVEVA System Platform to reuse graphics from existing applications to enable faster system design. It also includes a new graphical editor for procedural automation to improve operational effectiveness. This solution is compatible with IPCs, including Harmony P6 and ASRock.

The latest release has multi-OS compatibility with EcoStruxure Automation Expert HMI and Archive, now available on Linux and Windows, allowing users to develop objects with the same look and feel across all the compatible Operating Systems. These functionalities streamline engineering, improve operational effectiveness, and extend market capabilities.

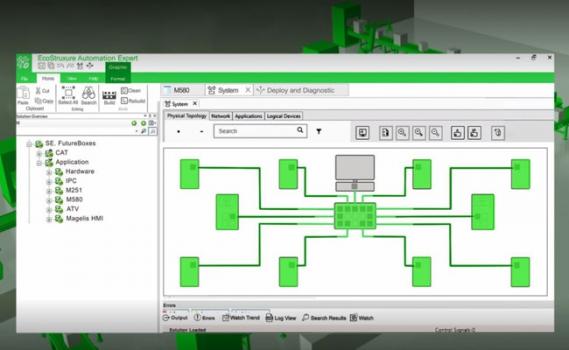

EcoStruxure Automation Expert is a next-generation industrial automation system changing the game by freeing equipment from closed, proprietary technology creating a universal automation platform. By uniting assets from different brands and systems with a common language and design, EcoStruxure Automation Expert is simplifying systems to drive innovation and reduce commissioning costs.

2022 NED Innovation Award Winner

EcoStruxure Automation Expert unlocks the promise of Industry 4.0 and unleashes productivity, speed, and efficiency at scale. This universal automation platform delivers a new approach to building/designing industrial automation systems by breaking down communications barriers that impede innovation.

Like the ‘IBM v. Mac’ compatibility issues in offices years ago, current automation systems pair hardware and software leading to ‘vendor lock-in’ keeping operators from accessing the latest technology when upgrading. By separating software and hardware, EcoStruxure Automation Expert is eliminating this challenge while advancing platform design, implementation, and management.

Users can now design an automation control system by connecting a digital representation of an asset to real-time control. These digital replicas enable testing and adjustments to be conducted in an online environment, leading to a significant reduction in conditioning time and cost, allowing for changes to be implemented faster, unlike traditional process control systems.

EcoStruxure Automation Expert’s support for mainstream IT best practices enables step-change improvements in asset and workforce efficiency using advanced technologies like predictive maintenance, digital twin, and others. The system also reduces the total cost of ownership by incorporating legacy systems with a wrap-and-reuse approach.

Update: October 2021

Version 21.2 focuses on helping future-proof water and wastewater plant operations; Water and wastewater plants will now have complete lifecycle management, seamless integration of IT/OT services, and improved system diagnostics for their automation systems. The solution also enables close integration with the AVEVA portfolio, further extending capabilities and options to add or modify as future needs arise.

EcoStruxure Automation Expert will provide a single platform that evolves with time for water and wastewater subsegments, including:

- Treatment infrastructures: water treatment and wastewater treatment plants, desalination plants, and industrial wastewater

- Network infrastructures: water and wastewater networks

- Water resources: distributed systems, such as irrigation systems

Update: May 2022

Version 22.0 focuses on consumer-packaged goods, logistics, and water & wastewater operations, offering enhancements including:

- Expanded libraries for segment functions and energy management devices

- Enhanced user experience (UX) in the build time tool

- Fortified built-in cybersecurity

- Support for additional engineering input formats, including DEXPI (ISO15926 based) and Excel

- Chinese, English, French, German, Italian, Portuguese, and Spanish language support and enhanced documentation

EcoStruxure Automation Expert can connect to AVEVA Engineering and import plant design data for automated bulk engineering. It also enables scalable visualization for the enterprise control room by integration with the AVEVA System Platform

Specs

- Improve your entire lifecycle and reimagine automation

- Decouple the automation application from the runtime hardware for remarkable agility

- Native IT/OT convergence to easily integrate advanced IT applications, tools, and technologies for industrial use

- Asset-centric design with ready-to-use asset models to eliminate low-value tasks, making it easier to wrap and reuse portable automation objects for maximum engineering efficiency

- Enables efficient wrap and reuse of automation objects to ensure you can make the most of what you already have and easily update and upgrade

- Provides rapid agility to process changes so you can design and reconfigure processes on the fly

- Bridges the division between IT and OT systems, so you can create operational effectiveness we could only dream of a decade ago

- EcoStruxure Automation Expert has been developed, following the IEC 61499 standard for portability and interoperability